Getting It Right From The Start

Our experienced team will review your architects’ drawings and can advise on value engineering and build-ability. Once finalised drawings are received our designers set to work following this information with precision.

Approval

After preparing detailed General Arrangement and Section drawings – these are submitted to the broader design team for approval.

Drawing Individual Components

Once designs are signed-off and all parties involved are happy to proceed, we then start detailing all individual wall, floor and roof components ready for manufacturing.

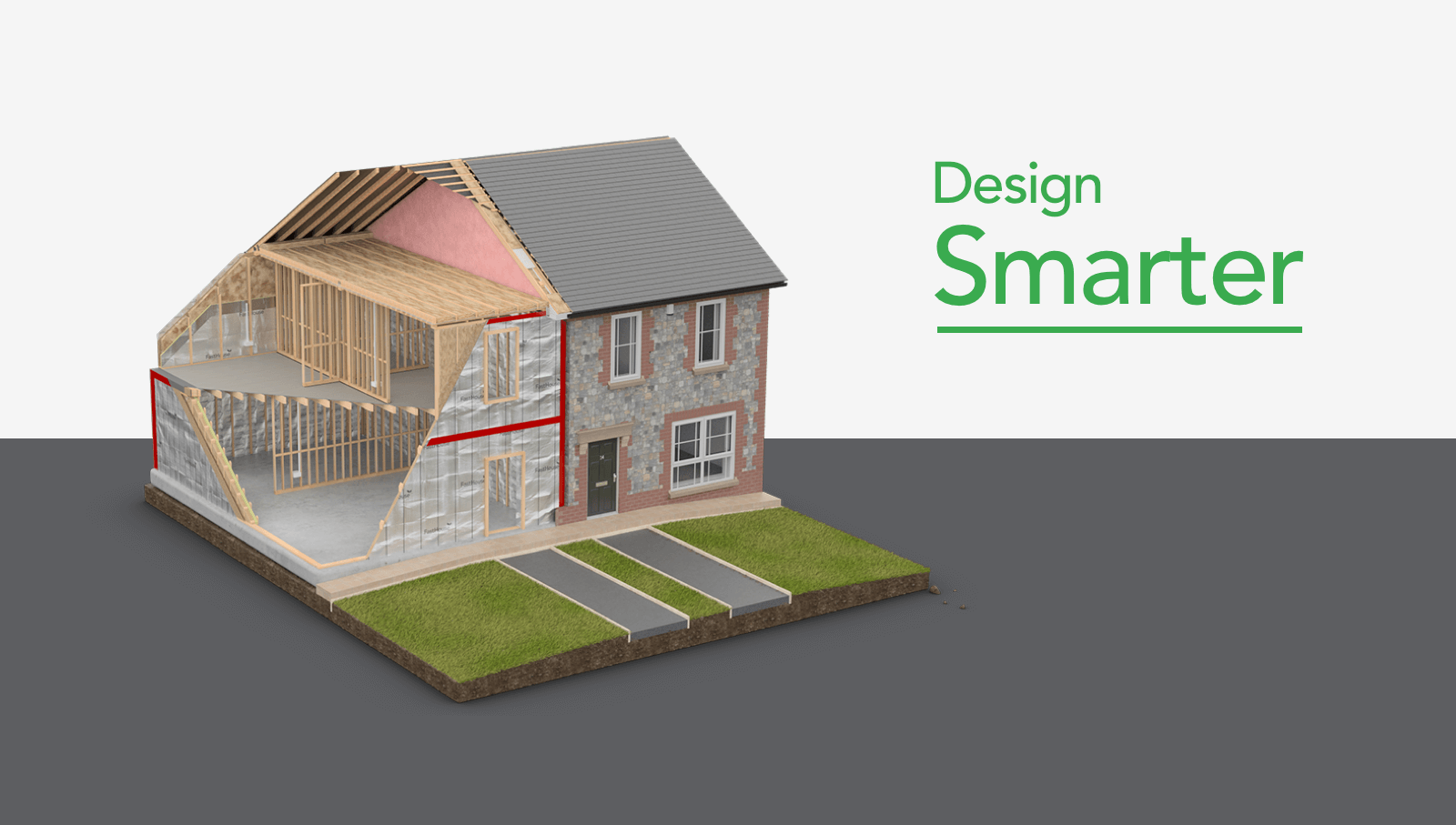

3D Renders

FrameTech have invested in the latest BIM-ready design software. The 2D drawings we issue to factory and to site are all extracted from a complete 3D model of the project, assembled by our CAD experts. We can walk through this virtual building to ensure everything fits together as it should.

Component Sign-Off

As part of our internal quality measures, and in accordance with ISO 9001 & STA Gold procedures, every individual component drawing is checked before manufacturing can begin.

Hand Over To Manufacturing

Once designs are verified, the finalised components are exported as digital files to our automated saws, truss presses and specialised panel assembly machines, and it’s over to our skilled production team.